The key to maintaining a profitable business lies in understanding and implementing fundamental principles that cut across various industries.

Toyota and Danaher's 4P Models for Business

Toyota and Danaher stated their priorities and repeated them obsessively. Here's the 4P framework that drives every decision at scale.

Want the secret sauce behind Toyota and Danaher’s success?

They purposefully state their priorities, their approach, and their principles.

They didn’t just state them—they repeated them in meetings and presentations. They reiterated them in the midst of problems. They preached them like a sermon to people both inside and outside of their company.

Why does this matter? Whether you state them explicitly or they are implied by daily decisions and conversations, they provide the needed reference for prioritizing work, decisions, and the application of your actual business.

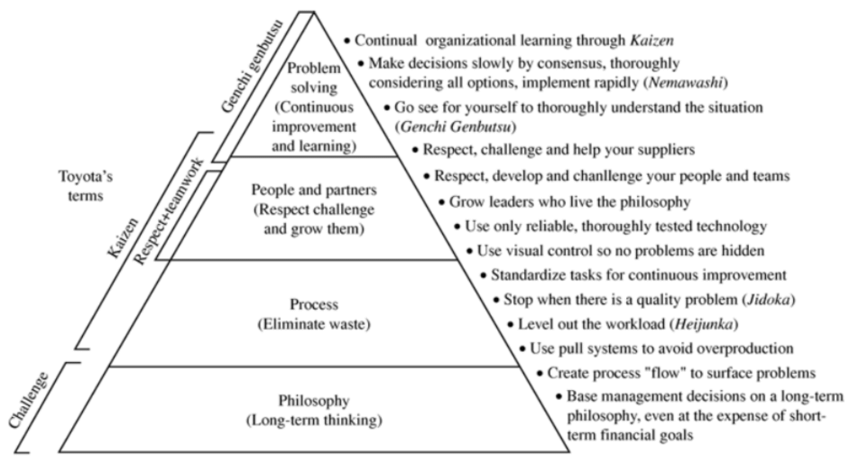

The Toyota 4P Model

Toyota laid out a simple yet powerful 4P model as the basis for their approach:

- Philosophy — Long-term thinking over short-term gains

- Process — Eliminate waste in time, material, energy, and resources

- People — Respect + challenge = growth

- Problem Solving — Continuous improvement through proper root cause analysis

Philosophy: The Foundation

Toyota’s philosophy was all about long-term thinking. Every decision gets filtered through: “Will this still be the right choice in 10 years?” This prevents the short-term optimization that kills companies—cutting training budgets, deferring maintenance, squeezing suppliers for quick savings.

Most small businesses I work with are stuck in firefighting mode. They make decisions based on this week’s cash flow, not this decade’s trajectory. The philosophy pillar forces you to step back and ask: what are we actually building here?

Process: Eliminating Waste

With philosophy as the foundation, Toyota then created processes to eliminate wasteful time, material, energy, and resources. They identified seven types of waste (muda):

- Overproduction — Making more than customers need

- Waiting — Idle time between process steps

- Transport — Unnecessary movement of materials

- Over-processing — Doing more than required

- Inventory — Excess stock tying up capital

- Motion — Unnecessary movement of people

- Defects — Rework and scrap

When I walk through a distribution center or manufacturing floor, I can usually spot 20-30% waste within the first hour. Most of it is hidden in plain sight because “that’s just how we do things.”

People: Respect and Challenge

Toyota wanted a culture of respect, but also one where people challenged each other and wanted to grow—not only individually, but as a team. This is the hardest pillar to implement because it requires genuine humility from leadership.

Respect means trusting frontline workers to identify problems. Challenge means expecting them to propose solutions, not just complaints. Most companies get one or the other. Toyota gets both.

Problem Solving: Continuous Improvement

Finally, they wanted continuous improvement in all areas of the company through proper problem-solving. This is where tools like the 5 Whys, A3 thinking, and PDCA (Plan-Do-Check-Act) come in.

The key insight: problem-solving is a skill that must be taught and practiced. Most employees have never been trained to systematically identify root causes. They jump to solutions, creating operational debt that compounds over time.

This idea was the basis for 14 specific management principles that governed the very ethos of the company and allowed them to run an extremely effective operation.

The Danaher 4P Model

Years later, Danaher created their own version of the 4P model known as the Danaher Business System (DBS):

- People — Exceptional talent with shared values

- Plan — Clear strategy and execution roadmap

- Process — World-class tools and methods

- Performance — Measurable results that compound

For them, these 4 aspects work together to create outstanding results. As they put it:

Exceptional PEOPLE develop outstanding PLANS and execute them using world-class tools to construct sustainable PROCESSES, resulting in superior PERFORMANCE. Superior performance and high expectations attract exceptional people, who continue the cycle.

This is a virtuous cycle. Great people create great results, which attracts more great people. But it starts with having the discipline to define what “great” means in your context.

Implementing the 4P Framework: A 12-Week Roadmap

Here’s how I’ve helped companies adopt these principles:

Weeks 1-3: Philosophy Clarity

- Define your 3-5 core tenets (what you will never compromise)

- Write them down in plain language (no corporate jargon)

- Pressure-test against recent decisions: would this tenet have guided us?

- Get leadership aligned—this requires honest conversations

Weeks 4-6: Process Mapping

- Map your core value stream (how work flows from order to delivery)

- Identify the top 5 waste sources (be specific, not general)

- Calculate the cost of each waste type annually

- Prioritize based on ease of fix vs. impact

Weeks 7-9: People Development

- Assess your team against the 4P competencies

- Identify skill gaps and training needs

- Create learning opportunities (shadowing, mentoring, courses)

- Start weekly problem-solving sessions with frontline teams

Weeks 10-12: Problem-Solving System

- Train the team on structured problem-solving (A3 or similar)

- Establish a visible management system (daily huddles, metrics boards)

- Track problems identified → solved → prevented

- Celebrate wins and share learnings across teams

Common Mistakes to Avoid

After implementing these frameworks across manufacturing, distribution, and home services companies, I’ve seen the same mistakes repeatedly:

1. Starting with tools, not philosophy. Companies buy expensive software or hire consultants to implement “lean” before defining what they actually believe. Tools without philosophy create cynical employees who’ve “seen this before.”

2. Treating it as a project, not a culture. The 4P framework is never “done.” Companies that assign it to a project manager and expect completion miss the point entirely.

3. Skipping the people pillar. Process improvements without people development create resentment. Employees feel like they’re being squeezed for productivity rather than supported for growth.

4. Expecting quick results. Toyota took decades to build their system. You won’t transform your culture in 90 days. The first year is about building foundations; the returns compound in years 2-5.

Expected Results

When implemented properly, companies typically see:

- 15-25% reduction in operational costs within 18 months

- 30-50% improvement in on-time delivery as processes stabilize

- 40-60% reduction in defects/rework through problem-solving discipline

- 20-30% improvement in employee retention as culture improves

The real ROI isn’t in any single metric—it’s in the compounding effect of a team that continuously improves.

Your Turn: Defining Your Core Tenets

Having a simple way to encapsulate your culture, philosophy, and approach won’t in and of itself transform anything. What it does is make it easier to remember, to reiterate, to preach it over and over again until it becomes ingrained in every aspect of your business.

So what are your values? What are your foundational concepts—what I call “core tenets”—that you are building everything on?

Start by asking:

- What do we believe about our customers that others don’t?

- What will we never sacrifice for short-term results?

- How do we expect people to treat each other?

- How do we make decisions when there’s no clear answer?

Write these down. Repeat them. Let them guide your hiring, your promotions, your daily decisions. That’s how Toyota and Danaher built world-class operations—not through complex systems, but through simple principles applied with relentless consistency.

Related Reading:

Every business runs on three machines: sales, operations, and finance. Master all three or one will bottleneck your growth.

“In my definition, an entrepreneur is someone who doesn’t just see the problems, but also sees the solutions, the opportunities.”